Many product teams start with plastic because the quote looks friendly. Then the field failures show up. You see warping under heat. You see cracking after UV exposure. You see assembly drift that turns a clean CAD model into a rework party.

At SSOSS Cast, we see this pattern most often in electronics housings, connector parts, small mechanical linkages, and hardware that gets handled every day. The part looks small. The tolerance stack is not.

Why choose zinc die casting instead of plastic injection or aluminium die casting?

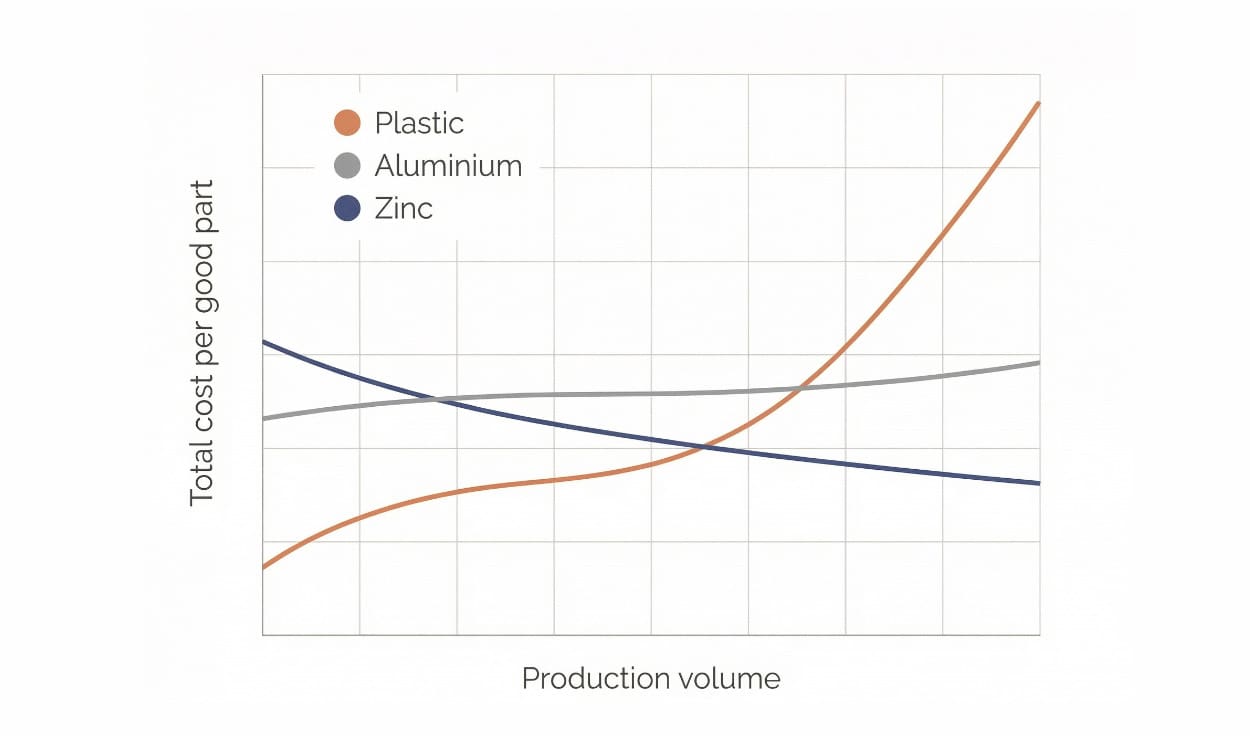

[Answer Capsule] Zinc die casting is a strong choice when you need repeatable tolerances, thin walls, and a premium surface finish at medium to high volume. Typical zinc tooling can reach around 1,000,000 shots, often more in well managed programs. Zinc’s low melting point supports faster cycles than aluminium in many applications. Plastic can win on unit cost, but it is more exposed to UV and heat driven degradation risks in real world use. (Zinc Die Casting)

Zinc is not for every part. If your top priority is ultra light weight, aluminium or engineered plastics may fit better. If your top priority is tight tolerance stability, crisp details, and a strong “click feel,” zinc usually becomes the safer bet.

Quick comparison table for decision makers

| Criteria | Zinc die casting | Aluminium die casting | Plastic injection moulding |

|---|---|---|---|

| Typical tooling life (well managed) | Often around 1,000,000 shots | Often lower than zinc in many programs | Can be high, depends on resin and tool steel |

| Thin wall capability | Often feasible around 0.5 mm with good design | Often needs thicker walls depending on part | Thin walls possible, but risk of sink and warpage rises with geometry |

| Cycle speed | Often faster due to lower melt temp | Often slower due to higher melt temp | Fast, but depends on cooling and gate design |

| Surface finish | Excellent, plating friendly | Good, often needs finishing for premium feel | Can look great, but cosmetic defects are common |

| Field risk in tropical UV and heat | Low compared to many plastics | Low | Higher, material dependent, UV can embrittle polymers over time |

Tooling life and wall thickness are design dependent. Use them as planning ranges, not promises. (Deco Products)

When does zinc become more cost effective than aluminium?

Aluminium is often chosen by habit. The problem is that “material choice” is not only weight and strength. It drives cycle time, defect risk, tool wear, and how much machining you need.

Zinc melts at about 419°C, which is much lower than aluminium. That lower process temperature is one reason zinc can run faster and preserve tooling better in many production environments. (DeZe Technology Co, Ltd)

A practical way to think about break even is this.

Break even logic that actually matches factory reality

Zinc becomes more cost effective when at least one of these is true:

- You need thin walls and tight tolerances, so aluminium would need extra machining to “save” the part.

- You want to avoid frequent tool refurbishment and downtime.

- Your program is medium to high volume and the cycle time difference matters.

Many industry references point to zinc tooling life around 1,000,000 shots as a typical range, with real examples going higher. Aluminium dies are often quoted at much lower shot counts depending on alloy, part design, and die management. (Zinc Die Casting – German)

SSOSS Cast also shares a case where an aluminium RF housing needed a full secondary CNC pass and had scrap issues around thin ribs. After changes, scrap dropped and machining was removed. That is often where the real money is. Not “metal cost,” but avoided rework. (SSOSS Cast Pte Ltd)

Can zinc fix common plastic injection moulding problems?

Plastic can be excellent when it is designed correctly and the resin is matched to the environment. The failures we see usually happen when a plastic part is doing a metal job.

1) UV and weather driven embrittlement

UV radiation can cause photo oxidative degradation in polymers, which reduces mechanical properties and can lead to cracking and brittleness over time. This is not a Singapore only problem. Singapore’s sun and heat simply make bad material choices show up faster. (PMC)

2) Creep and “loss of clamp” feel

Many plastics are viscoelastic. Under long term load, they can creep. Temperature and humidity can accelerate creep effects depending on polymer system and design. That matters for clips, latches, and parts that must keep a precise feel over thousands of cycles. (PMC)

3) Sink marks and cosmetic quality drift

Sink marks are a common injection moulding defect. They often happen around thicker sections where cooling and shrinkage are uneven. If your product is consumer facing, this can damage perceived quality even when function is fine. (Fictiv)

Zinc avoids these specific plastic failure modes. You still need proper DFM, gating, and draft. You just remove the polymer physics risk that shows up in harsh use.

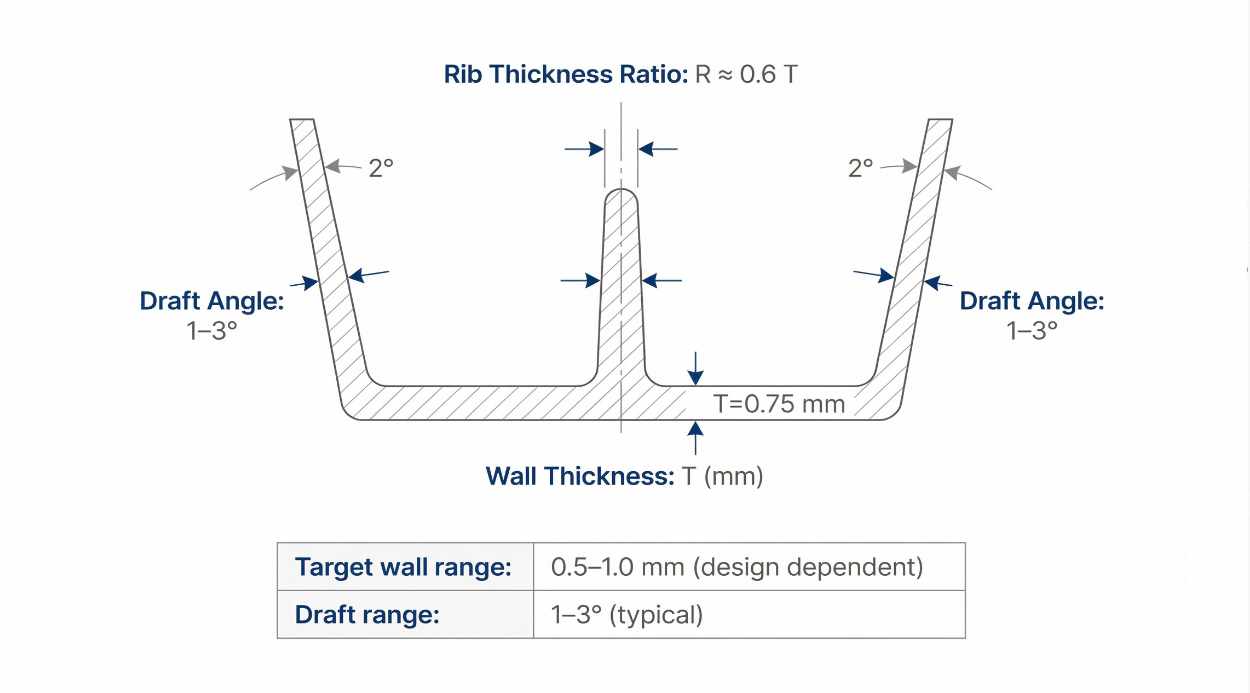

How thin can zinc die casting go for small precision parts?

Thin walls matter for two reasons. They reduce material. They also reduce cycle time.

Industry guidance commonly cites 0.5 mm to 1.0 mm as a practical minimum range depending on design, geometry, and strength requirements. Zinc industry design rules also discuss minimum practical wall sections that can go below 0.5 mm in short flow distances with the right gating strategy. (Dynacast)

SSOSS Cast highlights zinc alloy die casting for thin walls and intricate details. Their “About Die Casting” page also references Zamak 3 and why it is widely used for tight tolerances and good finishing acceptance. (SSOSS Cast Pte Ltd)

If you want a fast DFM check before cutting steel, use these three questions:

- Are wall thicknesses consistent, or do they jump abruptly?

- Are ribs sized to support, not to create hot spots?

- Is draft included everywhere the die needs release?

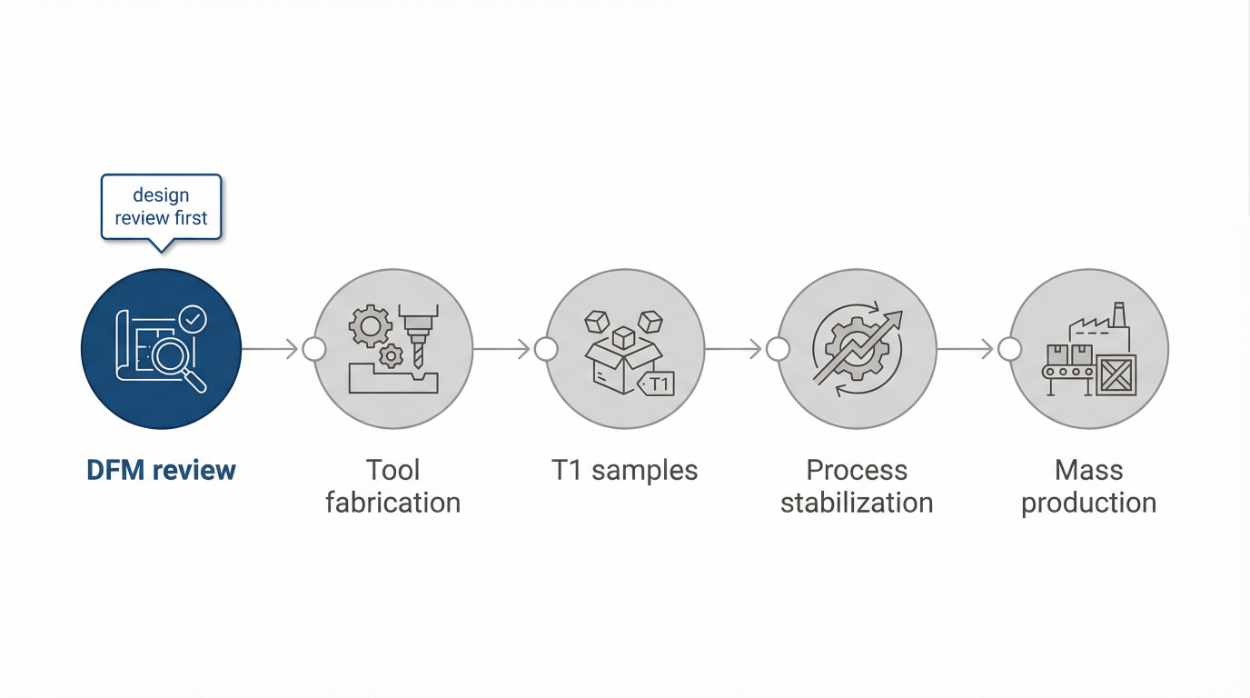

How SSOSS Cast supports faster production without sacrificing precision

A big pain point for Singapore OEM teams is coordination. The CAD team is here. The factory is elsewhere. The revision cycles get slow.

SSOSS Cast positions Singapore as the coordination hub and runs manufacturing from a facility near Xiamen, with their site describing the dual location setup and logistics advantage. (SSOSS Cast Pte Ltd)

They also highlight capabilities for larger precision zinc die castings up to 2.8 kg per shot while holding tight tolerances. That matters for programs that grow beyond tiny parts. (SSOSS Cast Pte Ltd)

A practical lead time mindset

Instead of asking “how fast is the first sample,” ask these:

- How fast can the supplier run design review and DFM feedback?

- How fast can they stabilize the process so your second batch matches the first?

- How fast can they add finishing and secondary operations without quality drift?

SSOSS Cast emphasizes a DFM led process flow and shares a case study framing that design review often prevents weeks of defect chasing later. (SSOSS Cast Pte Ltd)

Surface finishing that makes zinc look premium

Zinc is popular for parts that need both precision and a premium look. It accepts a wide range of finishes.

SSOSS Cast offers surface finishing and electroplating as part of their service stack, and they show product categories like chrome plated zinc die casting. (SSOSS Cast Pte Ltd)

Common finish goals we see:

- Chrome plating for high gloss, premium hardware and visible components.

- Powder coating for durability and color stability.

- Raw tumbled finish for functional parts where appearance is secondary.

If your product is customer facing, finishing is not decoration. It is part of quality perception and sometimes corrosion behavior.

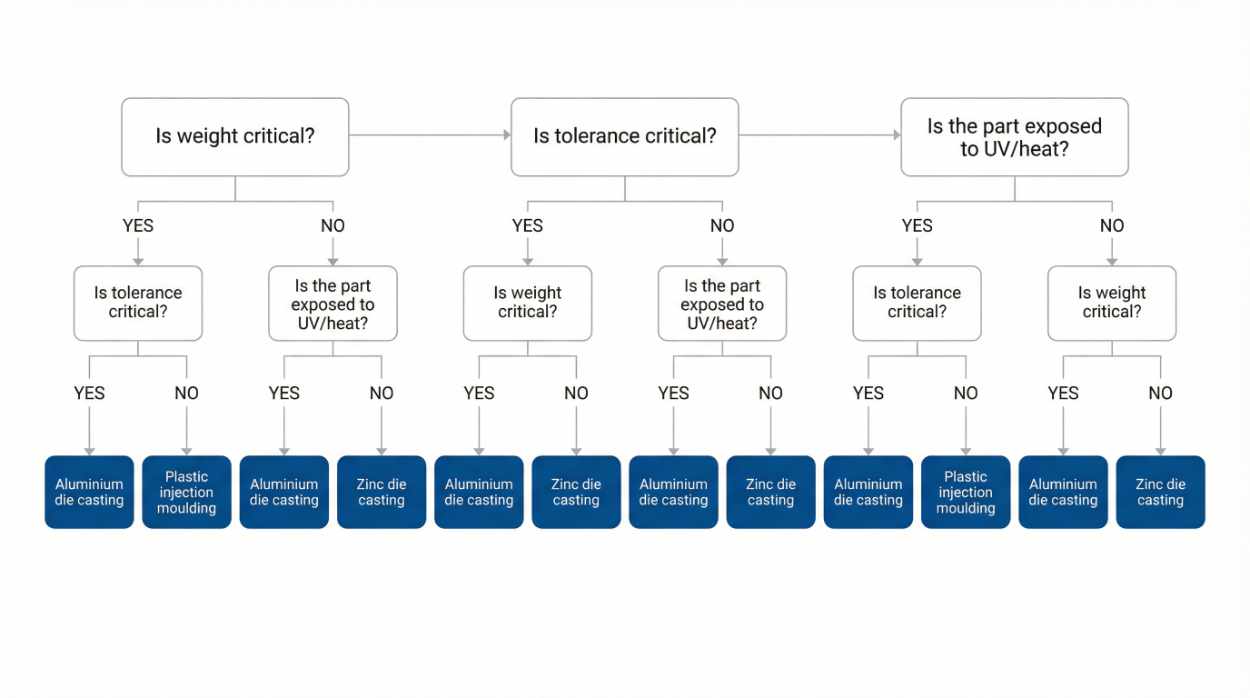

A simple buyer checklist for choosing zinc vs plastic vs aluminium

If you are an SME director or operations manager, you do not want theory. You want fewer defects and stable supply.

Use this checklist before you commit.

Choose zinc die casting when

- You need repeatable dimensions in production, not only on the first sample.

- You need thin walls, sharp edges, and crisp features.

- You want to reduce machining and assembly rework.

- The part is handled often and “feel” matters.

Choose aluminium die casting when

- Weight is critical.

- The part is larger and structural, and wall thickness is not ultra thin.

- You can tolerate more machining or you already have a stable aluminium process.

Choose plastic injection moulding when

- Weight is critical and loads are low.

- You can select a resin that survives heat and UV exposure for your actual use case.

- Cosmetic defects and creep are managed by design and process control.

FAQ

What zinc alloy is commonly used for high precision parts?

Zamak 3 is widely used. SSOSS Cast states it is a popular zinc alloy and notes its strength, ductility, castability, and tight tolerances among zinc alloys. (SSOSS Cast Pte Ltd)

What is a realistic tooling life expectation for zinc?

Many industry sources cite around 1,000,000 shots as a typical die life range for zinc tooling, with examples exceeding that under good conditions. Your actual result depends on part design, die design, and maintenance discipline. (Zinc Die Casting – German)

How fast is zinc die casting compared to aluminium?

Zinc’s lower melting point supports faster processing in many scenarios. Some manufacturing references describe zinc cycle rate as about 150% to 200% higher than aluminium in certain comparisons. Always validate with your part geometry and machine tonnage. (rapiddirect)

Can zinc die casting reduce machining?

Often yes, especially when the design is optimized for net shape features. SSOSS Cast shares a case where machining stages were eliminated after changes, along with a major scrap reduction. (SSOSS Cast Pte Ltd)

What is a quick way to start with SSOSS Cast?

Start with a design review and target outcomes. For example, reduce scrap, remove a CNC pass, improve surface finish, or tighten tolerance on a critical interface.

Internal links you can add in WordPress

SSOSS Cast homepage and capabilities https://www.ssosscast.com/ (SSOSS Cast Pte Ltd)

About die casting and zinc alloy basics https://www.ssosscast.com/about-die-casting/ (SSOSS Cast Pte Ltd)

About SSOSS Cast and capability highlights https://www.ssosscast.com/about-us/ (SSOSS Cast Pte Ltd)

Contact SSOSS Cast https://www.ssosscast.com/contact-us/ (SSOSS Cast Pte Ltd)

Example product category for chrome plated zinc parts https://www.ssosscast.com/product-category/precision-zinc-die-casting/chrome-plated/ (SSOSS Cast Pte Ltd)