In April 1995, SSOSS Cast Pte Ltd started our first production factory in Larkin Industrial Estate, Johor, Malaysia.

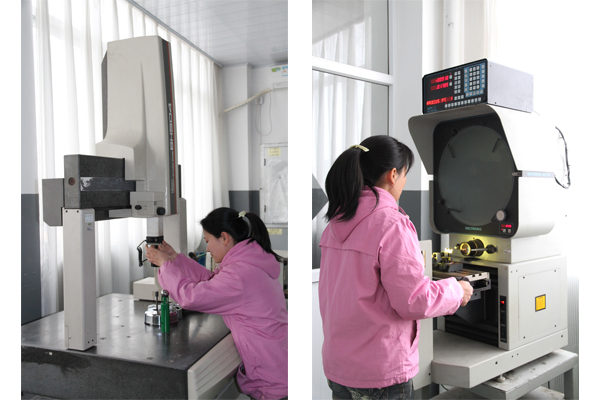

In 1997, to expand and globalize our operation, SSOSS CAST purchased a piece of land in Quanzhou (Fujian Province, China) and built its own Zinc Die Casting Factory. In 1998, the operation in Malaysia was transferred to China. To support the China operations, SSOSS CAST also set up head office in Singapore to co-ordinate orders, shipments and sales enquiries.

While our head office is situated in Singapore, our production facility is located in China just 60 km from Xiamen International Airport/Container seaport. With excellent logistic links, we are able to ship our products conveniently and efficiently around the world.

With an administrative head office in Singapore and a factory in China, SSOSS CAST is able to serve our customers efficiently and supply them with high quality and cost effective Zinc Die Cast Components. SSOSS CAST’s customers span around the globe and include companies from South East Asia, Japan, America, and Europe.