Supplying parts to customer specifications. ZERO DEFECTS

Plastic Injection Moulding provides precision-engineered plastic components for telecommunications industries, delivering exceptional durability and cost-effective manufacturing solutions

Ssoss Cast Plastic Injection Moulding: Manufacturing Excellence

Injection moulding stands as the ultimate manufacturing solution for modern product development, providing an ideal combination of performance, aesthetics, and cost-effectiveness. This technology is preferred by industry leaders in consumer electronics, general consumer products, and telecommunications for its unmatched blend of durability and design flexibility. Contemporary ABS formulations support sustainability through effective recycling capabilities, aligning with circular economy principles while maintaining high performance standards. The injection molding process excels in mass production scenarios, creating thousands or millions of identical parts in succession.

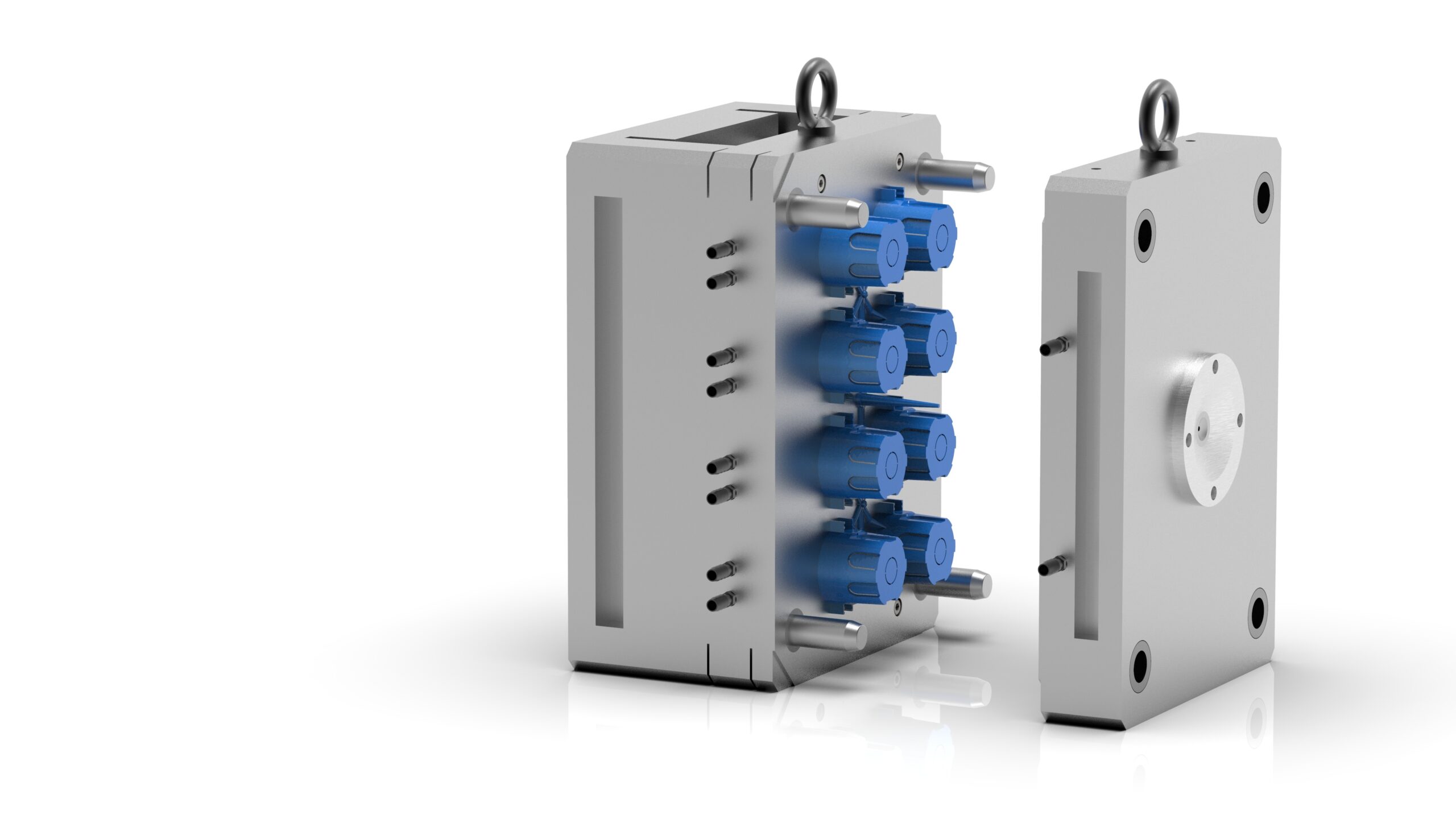

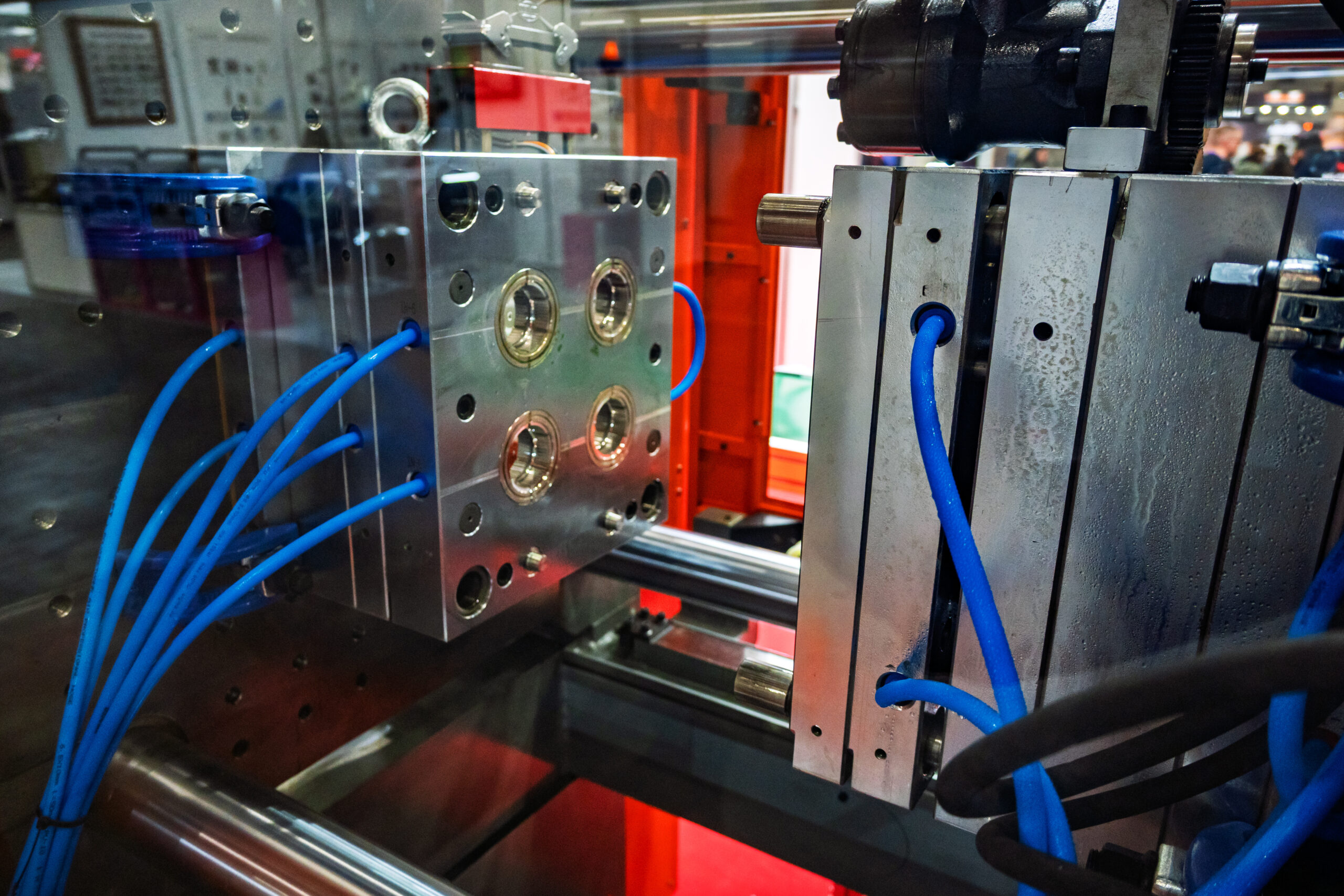

Injection molds are precision steel tools with stationary and moving sections, featuring parting lines, gates, cooling channels, and vents. The process uses thermoplastics like ABS and nylon for diverse applications, delivering high accuracy, complex shapes, and automated production with minimal waste.

ABS injection moulding offers temperature tolerance (-40°C to 85°C) with lightweight strength. Processing benefits include easy flow, fast cycles, low shrinkage, excellent moldability, and strong weld lines. Surface advantages feature smooth finishes, printability, texturing, and colour versatility.

Our Customer Care and Support Center is dedicated to providing expert assistance, timely responses, and reliable solutions for all customer inquiries.

Ssoss Cast harnesses ABS’s remarkable properties, including exceptional impact resistance at low temperatures, superior surface quality with versatile finishing options, excellent flow characteristics for complex geometries, outstanding dimensional stability across varying conditions, and cost-efficient processing with quick cycle times. While requiring initial tooling investment, this manufacturing method delivers extremely low unit costs at scale, making it the preferred choice for products demanding excellence in both form and function without sacrificing manufacturing efficiency.

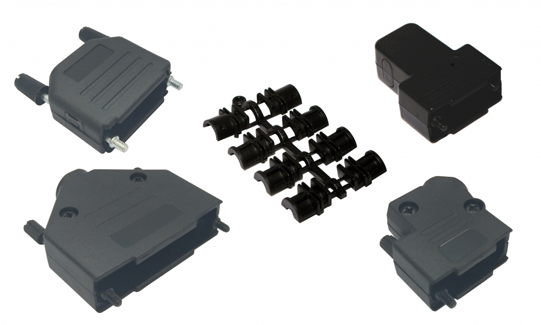

Protective D-sub hoods house and provide cable strain relief for connectors. Manufactured using injection molding with black ABS plastic, offering an optimal balance of protection, durability, and cost-effectiveness.

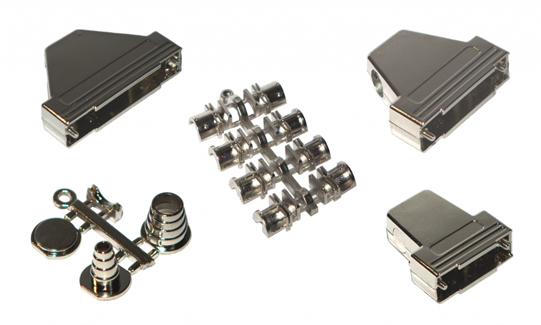

Copper/nickel plated D-sub hoods are advanced protective housings that combine injection molded plastic construction with superior EMI/RFI shielding through conductive metallic coating applied over the base material.

A shiny injection mould is a reusable template that transforms melted plastic into finished products with speed and precision. Its mirror-like surface ensures perfect parts through manufacturing magic happening thousands of times daily worldwide. Every plastic item you use was shaped by these remarkable moulds