Ssoss Cast pride ourselves in the range of electroplating and metal finishing services offered. With years of experience the company continues to grow and offers new finishes to satisfy market demands. Some of the specialist services offered include electroless nickel plating, antique finishing, selective plating, precision masking and multiple finishes. Ssoss Cast offer specialist electroplating services to various industries. We have been supplying plated OEM parts to some of the largest marine controls and telecommunication companies across the globe for decades.

Electroplating and Anodising

Industrial Products

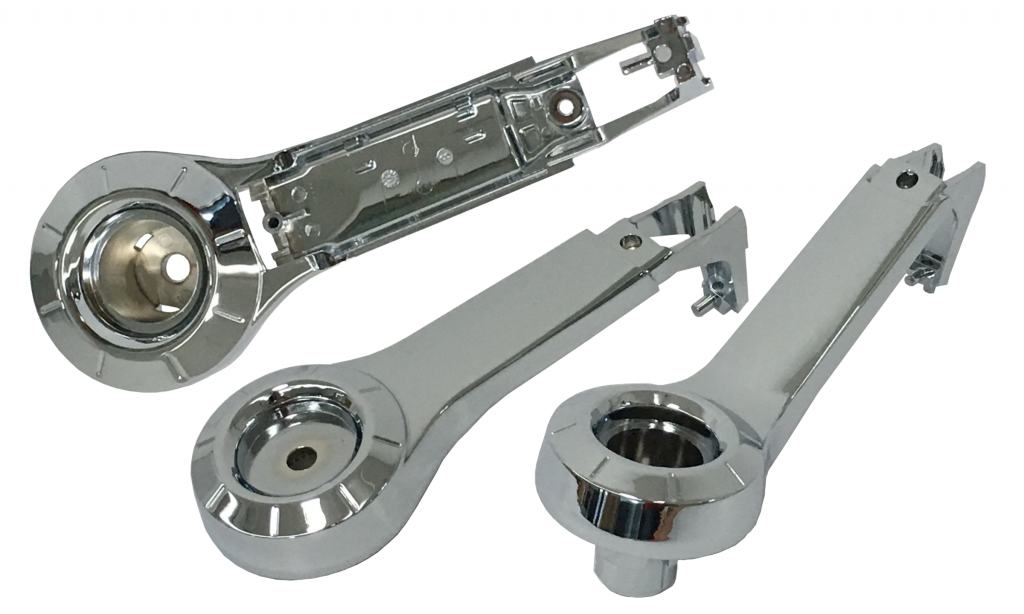

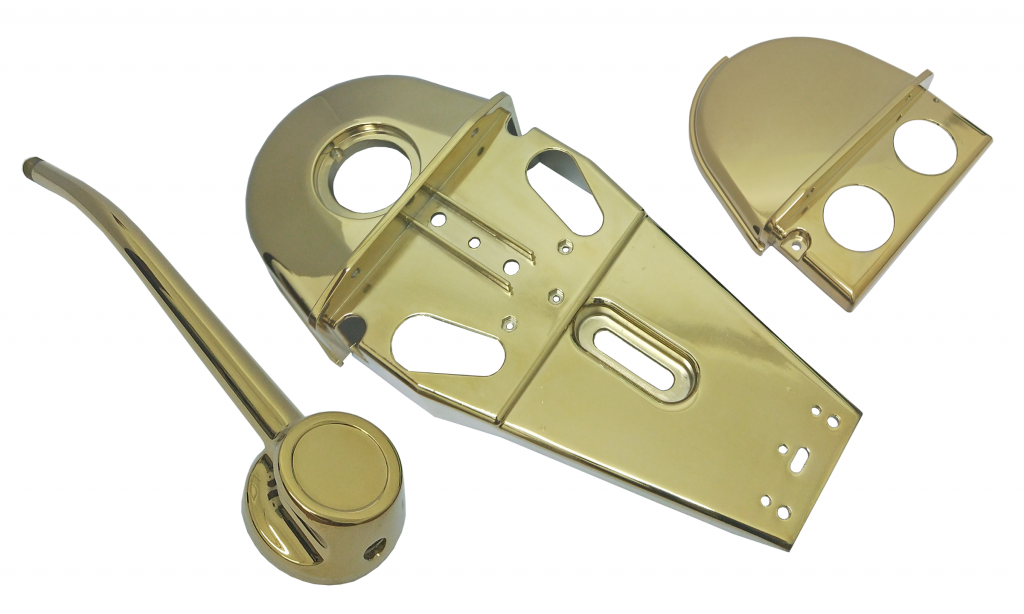

Copper, Nickel & Chrome electroplating

Electroplating is the process of applying one or more layers of a metal to a part by passing a positively charged electrical current through a solution containing dissolved metal ions (anode) and a negatively charged electrical current through your part to be plated (cathode). Our rack and barrel chromium plating, copper/nickel base provides wear/corrosion resistance that is ideal for marine environment and industrial applications. With graded passing on salt-spray test of at least 500 hours.

Trivalent chrome plating

New “green” trivalent chromium eliminates the health and environmental concerns associated with hexavalent chrome plating. In addition, trivalent chrome plating has better “throwing power”, allowing for more uniform deposit thicknesses on your product. Trivalent chrome does a better job of depositing metal in recessed areas and is less inclined to plate excessively thick deposits in high current density areas. Our new “green” trivalent chrome baths are setup to provide both bright “mirror” finishes and the new attractive dark color chromes.

Physical Vapor Deposition (PVD)

Ssoss Cast offers Physical Vapor Deposition – also known as PVD Coating which is a variety of thin film deposition techniques where solid metal is vaporized in a high vacuum environment and deposited on electrically conductive materials as a pure metal or alloy coating. This is usually done after chrome plating process.

Anodising

Ssoss Cast offers anodizing on aluminium parts which creates a non-conductive protective coating. To achieve maximum corrosion resistance, anodized particles are boiled in a solution of nickel acetate, which effectively seals the submerged parts.